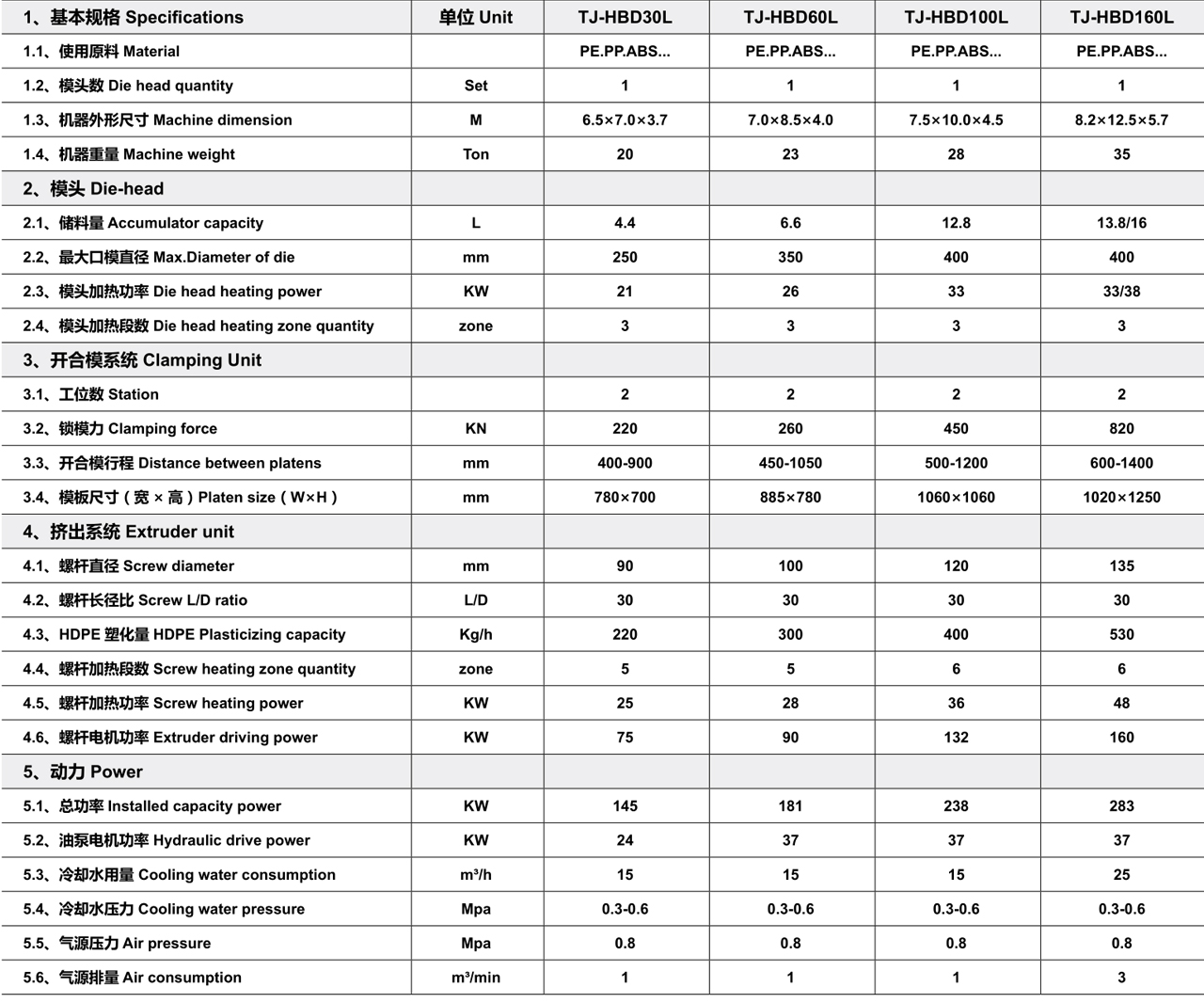

TJ-HBD30L-160L Double station hollow blow molding machine

Tongjia TJ-HBD30L-160L series double-station hollow blow molding machine can be customized according to the actual situation of customers to meet various requirements of different customers.

Add to quote| Clamping system: Double stations translation + High-precision linear guideway |

| Extrusion system:Hardened face gear reducer + Imported frequency inverter |

| Die System: Special Steel Center Feed Extrusion Die |

| Hydraulic system: All imported hydraulic valve, seal parts + Electro-hydraulic proportional control. |

| Control system:Imported PLC + Imported Human-machine interface + PLC automatic temperature control module |

Note: The above data is for reference only, the company reserves the right to modify the components and mechanical structure, and the relevant content involved in the purchase of equipment is subject to the contract.