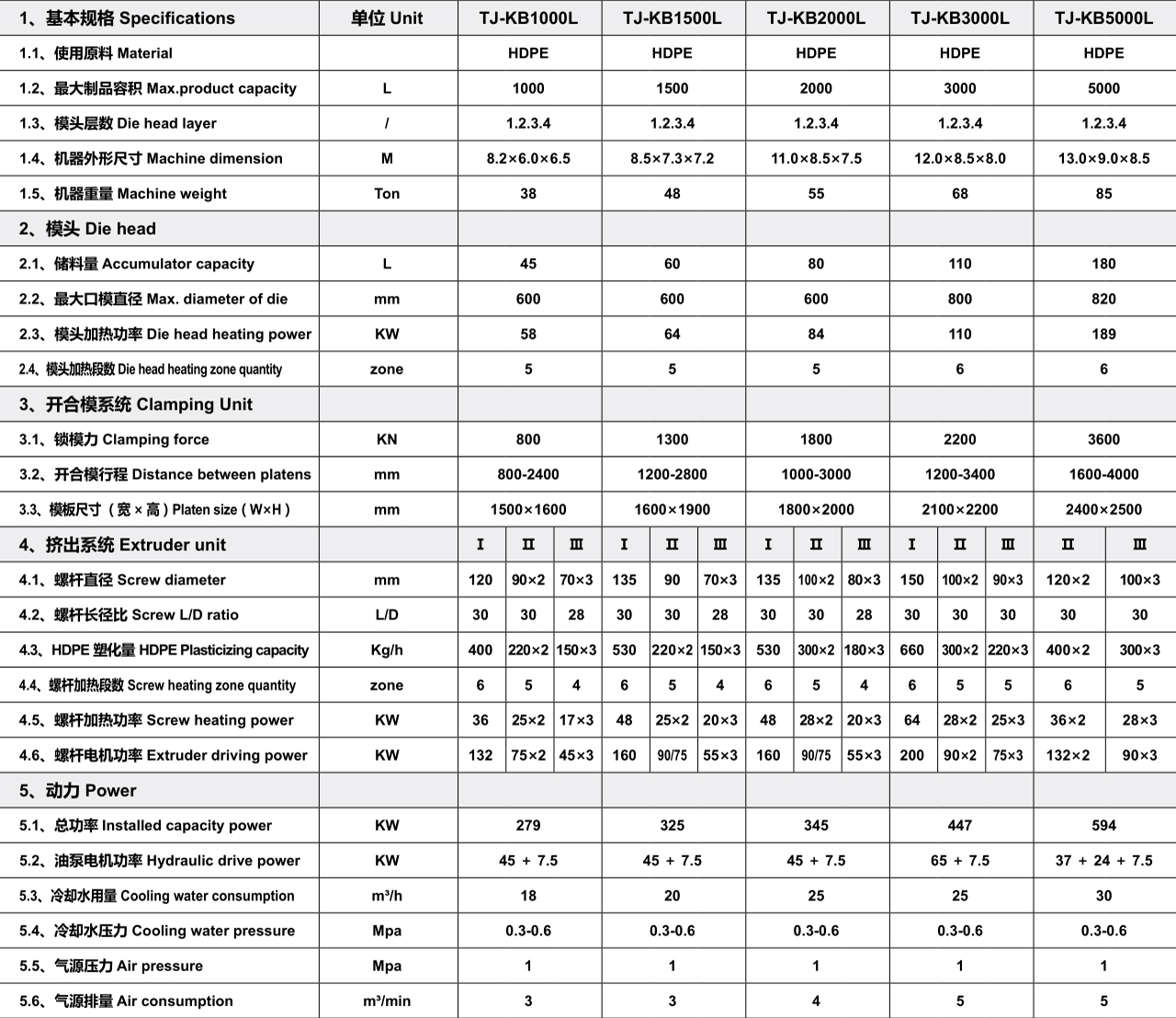

TJ-KB1000L-5000L Large Blow Molding Machine

Tongjia tj-kb1000l-5000l Series hollow blow molding machine is a blow molding machine developed for 200l-5000l civil barrels, water storage tanks, septic tanks and other large hollow products. The advantage of this series of blow molding machine is that it can process high molecular polyethylene, and its strength is higher than that of similar products on the premise of light weight. This series of hollow blow molding machines can be equipped with 2-5 layers of composite storage die according to the requirements of different products.

Add to quoteTongjia TJ-KB1000L -5000L series blow molding machine is a blow molding machine developed for 200L-5000L water tanks, septic tanks and other large hollow products. The advantage of this series of blow molding machines is that they can process high molecular weight polyethylene. Products made from high molecular weight polyethylene are lighter and more strength than similar products. This series of blow molding machines can use 2-5 layers storage die head according to customer requirements.

| Clamping system: Diagonal double tie bar center clamping bi-directional synchronous high precision linear guideway clamping device |

| Extrusion system: AC speed control + Hardened face gear reducer |

| Die system: Special steel center-feeding die |

| Hydraulic system: All imported hydraulic valve + hydraulic servo control system |

| Control system: Imported PLC + Europe imported complete machine control system (GEFRAN from Italy) |

Note: the above data are for reference only. The company reserves the right to change the components and mechanical structure. The relevant contents involved in the purchase of equipment shall be subject to the contract.