TH1280/SP Injection Molding Machine

TH1280/SP injection molding machine adopts brand name and is supplemented by hydraulic system and electrical system. Its product performance is stable, and various engineering operations are simple. It is widely used in aerospace, high-speed rail, automotive electronics, urban construction, people’s livelihood and other fields. TH Beyond series dedicated servo energy-saving injection molding machine is equipped with a pressure feedback device with strong precision and sensitivity, forming a closed-loop precision control and providing customers with good product stability. Compared with traditional hydraulic presses, it shows stronger injection stability, greatly improves the qualified rate of molded products, saves energy and protects the environment, responds quickly, effectively shortens the cycle, and improves production efficiency.

Add to quoteITEMS | Units | TH1280/SP | ||||

A | B | C | D | |||

INJECTION UNIT | Screw Diameter | mm | 110 | 120 | 130 | 140 |

| Screw L/D Ratio | L/D | 24.2 | 22.0 | 20.2 | 18.6 | |

| Theoretical injection Volume | cm3 | 5226.8 | 6220.3 | 7300.3 | 8466.6 | |

| Injection Weight (PS) | g | 4756.4 | 5660.5 | 6643.2 | 7704.6 | |

| Injection Pressure | Mpa | 197.9 | 166.3 | 141.7 | 122.1 | |

CLAMPING UNIT | Clamping Force | KN | 12800 | |||

| Clamping Stroke | mm | 1300 | ||||

| Space Between Tie Bar | mm | 1260×1260 | ||||

| Max. Mold Height | mm | 1260 | ||||

| Min. Mold Height | mm | 550 | ||||

| Eject Stroke | mm | 350 | ||||

| Eject Force | KN | 270 | ||||

OTHERS | Max. Pump Pressure | MPa | 16 | |||

| Approx. Motor Power | KW | 94.2/111.4 | ||||

| Approx. Heat power | KW | 84 | ||||

| Hopper Capacity | L | 200 | ||||

| Oil Tank Capacity | L | 1300 | ||||

| Dimensions | M | 12.6×2.73 ×2.9 | ||||

| Approx. Machine Weight | T | 58 | ||||

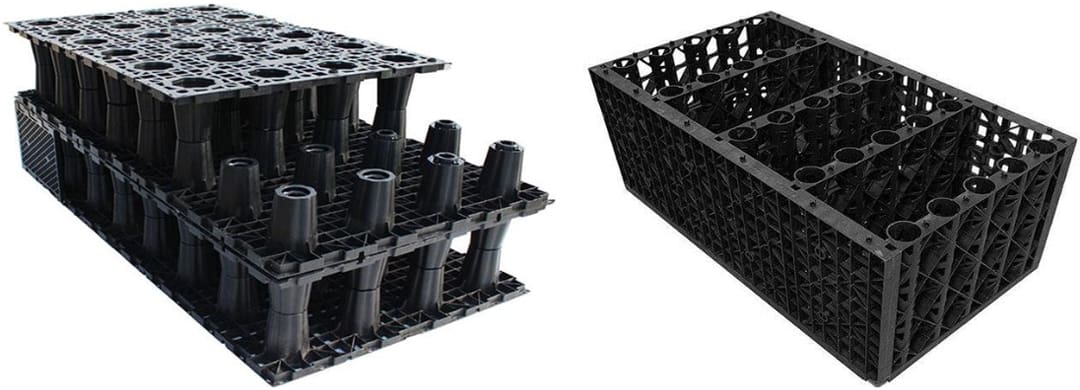

Our company's rainwater collection module equipment, the products produced by servo energy-saving injection molding machines, have reached high-quality manufacturing process standards, and we choose energy-saving rainwater collection module injection molding machine equipment----Tongjia Super Series TH1280/sp, which has been working with domestic and foreign customers. Successfully developed and launched to the market. The rainwater collection module is a one-time injection molding of molten PP plastic by injection molding machine equipment, and buried in the ground through a professional construction team to collect rainwater. Market prospect: Due to the rapid development of urbanization, the impervious areas of roads and buildings are expanding. On the one hand, rainwater cannot penetrate into the ground to replenish groundwater, and water resources are over-exploited, which makes the water environment and ecological environment around the city worse; The collection and utilization of water environment and rainwater resources have become increasingly prominent, and rainwater collection modules have emerged as the times require, which are emerging energy-saving and environmentally friendly injection molding products advocated by the state. Our company's rainwater collection module injection molding machine injection molding products have high molding rate, large output, time saving and power saving, and the machine is easy to operate. The rainwater collection module that participated in the design has flexible design, long service life, convenient construction, short construction period, fast transportation, strong bearing capacity, environmental protection and low cost. It is installed and used in the pilot sponge cities of Nanjing, Shanghai and Shenzhen, with huge market prospects and potential for development. Our company's injection molding machine has achieved win-win cooperation with customer companies, and meets the needs of the market environment. Rainwater harvesting module manufacturers are very profitable. Welcome friends from all walks of life to visit our Tongjia Heavy Industry for inspection and guidance.