TH1580/SP Injection Molding Machine

TH1580/SP injection molding machine adopts professional brand and is supplemented by precision hydraulic system and electrical system. Its product performance is stable, and various engineering operations are simple. It is widely used in aerospace, high-speed rail, automotive electronics, urban construction, people’s livelihood and other fields. This series of high-speed precision servo energy-saving injection molding machines is equipped with a high-precision and high-sensitivity pressure feedback device, forming a closed-loop precision control, providing customers with good product stability. Compared with the traditional hydraulic press, it shows stronger injection stability, greatly improves the qualified rate of molded products, saves energy and protects the environment, responds quickly, effectively shortens the cycle, and improves production efficiency.

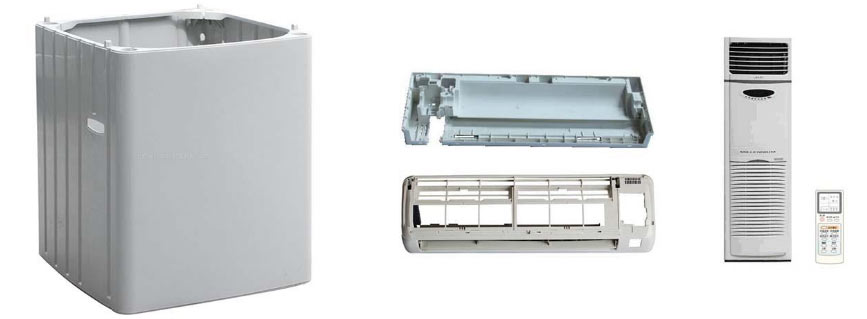

Add to quoteAir conditioner shells, TV bodies, and other household appliances shells are all injection-molded products that are molded by one-time injection molding machines. Different types of raw material particles are used according to the use and quality requirements of the products, and modified fiber materials are appropriately added to increase the product's quality. Flexibility and surface gloss. Our company's high-speed precision servo energy-saving injection molding machine TH1580/SP can be used to produce air conditioner shells and various home appliance bodies. It has provided several sets of air conditioner shells suitable for the production of this series of air conditioner shells for the domestic well-known air conditioner brand - a first-level supporting manufacturer of a force. The injection molding machine model has been recognized by the air-conditioning shell supporting manufacturers, and has also been highly praised by air-conditioning manufacturers. With the rapid development of the plastics industry and the continuous introduction of various new technologies and new plastic materials, the production and processing of plastic packaging, auto parts, various home appliance shells and even the advent of new environmentally friendly household products have entered a new period. Welcome friends from all walks of life to visit our Tongjia Heavy Industry to inspect the air conditioning shell injection molding machine equipment, and wholeheartedly provide you with the whole plant equipment plan!

ITEMS | Units | TH1580/SP | ||||

A | B | C | D | |||

INJECTION UNIT | Screw Diameter | mm | 120 | 130 | 140 | 150 |

| Screw L/D Ratio | L/D | 23.8 | 22.0 | 20.4 | 19.1 | |

| Theoretical injection Volume | cm3 | 6774.5 | 7950.7 | 9220.9 | 10585.2 | |

| Injection Weight (PS) | g | 6164.8 | 7235.1 | 8391 | 9632.5 | |

| Injection Pressure | Mpa | 195.6 | 166.6 | 143.7 | 125.2 | |

CLAMPING UNIT | Clamping Force | KN | 15800 | |||

| Clamping Stroke | mm | 1520 | ||||

| Space Between Tie Bar | mm | 1460×1360 | ||||

| Max. Mold Height | mm | 1400 | ||||

| Min. Mold Height | mm | 650 | ||||

| Eject Stroke | mm | 350 | ||||

| Eject Force | KN | 284 | ||||

OTHERS | Max. Pump Pressure | MPa | 16 | |||

| Approx. Motor Power | KW | 124/134 | ||||

| Approx. Heat power | KW | 89.3 | ||||

| Hopper Capacity | L | 200 | ||||

| Oil Tank Capacity | L | 2000 | ||||

| Dimensions | M | 14.5×3.9×3.8 | ||||

| Approx. Machine Weight | T | 70 | ||||