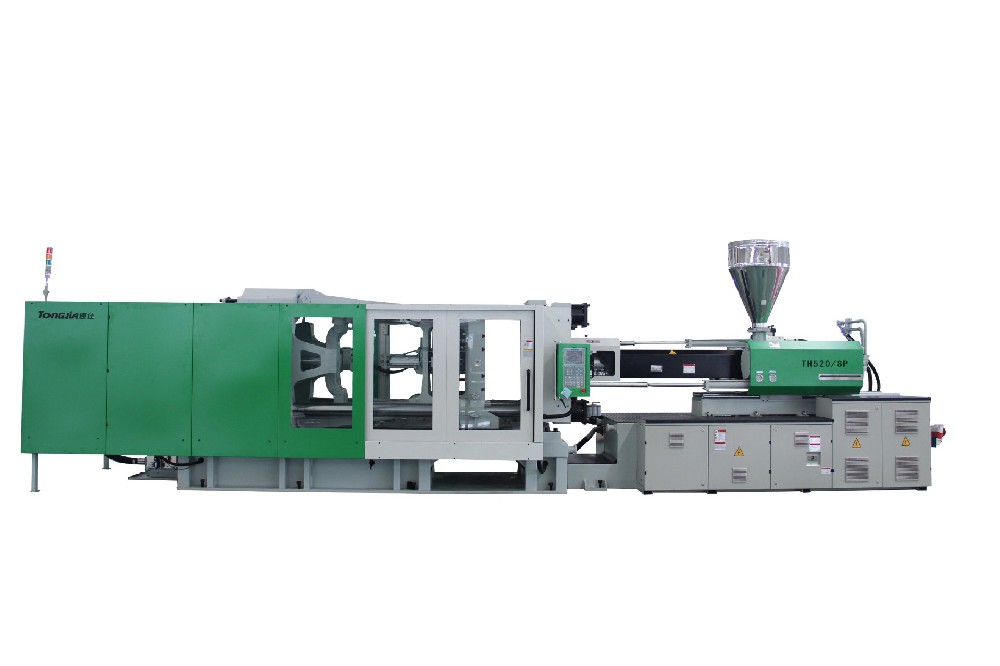

TH520/SP Injection Molding Machine

TH520/SP injection molding machine adopts brand name and is supplemented by hydraulic system and electrical system. Its product performance is stable, and various engineering operations are simple. It is widely used in aerospace, high-speed rail, automotive electronics, urban construction, people’s livelihood and other fields. This series of fast and precise servo energy-saving injection molding machines is equipped with a pressure feedback device with strong precision and sensitivity, forming a closed-loop precision control and providing customers with good product stability. Compared with traditional hydraulic presses, it shows stronger injection stability, greatly improves the qualified rate of molded products, saves energy and protects the environment, responds quickly, effectively shortens the cycle, and improves production efficiency.

Add to quoteITEMS | Units | TH520/SP | |||

A | B | C | |||

INJECTION UNIT | Screw Diameter | mm | 80 | 85 | 90 |

| Screw L/D Ratio | L/D | 22.3 | 21 | 19.8 | |

| Theoretical injection Volume | cm3 | 2030.7 | 2292.5 | 2570.1 | |

| Injection Weight (PS) | g | 1848 | 2086.2 | 2338.8 | |

| Injection Pressure | Mpa | 190.3 | 168.6 | 150.4 | |

CLAMPING UNIT | Clamping Force | KN | 5200 | ||

| Clamping Stroke | mm | 840 | |||

| Space Between Tie Bar | mm | 820×820 | |||

| Max. Mold Height | mm | 800 | |||

| Min. Mold Height | mm | 320 | |||

| Eject Stroke | mm | 200 | |||

| Eject Force | KN | 125 | |||

OTHERS | Max. Pump Pressure | MPa | 17.5 | ||

| Approx. Motor Power | KW | 62/65 | |||

| Approx. Heat power | KW | 38.8 | |||

| Hopper Capacity | L | 50 | |||

| Oil Tank Capacity | L | 800 | |||

| Dimensions | M | 9.0×1.96×2.54 | |||

| Approx. Machine Weight | T | 20 | |||

Our company's turnover basket injection molding machine production equipment TH520/sp high-speed precision servo energy-saving injection molding machine, energy saving and environmental protection, high efficiency and low loss. For plastic basket products, the clamping mechanism has a large depth and five fulcrum force-increasing design for product injection molding, which is very suitable for the production of turnover baskets. The whole machine adopts high-precision well-known displacement sensors, solenoid valves, hydraulic and other core system accessories, which are superior to those in the same industry. The servo motor adapts to the production cycle of the product. The cooling and pressure holding stage can save you 30% to 70% of the power consumption, and the production cycle is as high as two to three per minute. Market prospects: Plastic turnover baskets are widely used in a wide range of industries. The products are made of new polyethylene PE materials or recycled materials by one-time injection molding. They are durable, flexible, and resistant to temperature and acid and alkali corrosion. In recent years, the industrialization of new material plastic turnover baskets and disposable plastic turnover baskets has benefited from the vigorous development of modern logistics. Features. Our company's plastic turnover basket injection molding machine equipment plays a key role in saving packaging costs and improving transportation efficiency for vegetable production bases, fruit industry areas, seafood transportation and other industries, and has been well received by customers and customer manufacturers.