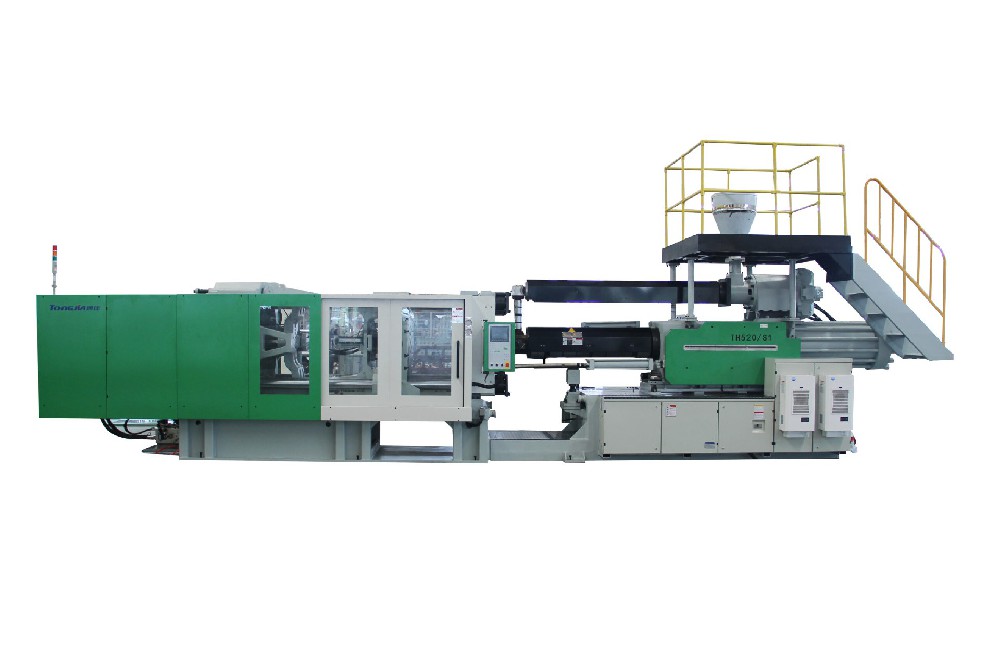

TH630/S1 Injection Molding Machine

TH630/S1 injection molding machine adopts brand supplemented by hydraulic system and electrical system. Its product performance is stable, various engineering operations are simple, energy saving and environmental protection (plasticizing screw, heating system, hydraulic motor, servo oil pump, etc.), further reducing product cost and improving Enterprise market competitiveness.

Add to quoteInjection part: the machine occupies less land, saves plant land, and reduces the length of the machine by 35%, saving capital construction investment; The screw does not retreat, the aspect ratio is constant, the actual aspect ratio is constant, the process of raw material transportation remains unchanged, the melt has no axial temperature difference, the plasticization quality has nothing to do with the product quality, the plasticization is good, and the back pressure is stable. The molding temperature is reduced, the product pressure is better, the internal pores are reduced, the surface quality is uniform, the product quality is good, and the large product quality is better; the injection precision is strong, no check ring design, no reverse material during injection, and injection weight repeatability is strong, Reliable sealing of plunger and valve core, long service life of high temperature seals, special sealing design, excellent sealing performance; low loss and maintenance-free, no screw head, non-return ring, sealing ring, very few wearing parts, and the same injection Compared with the ordinary machine screw, the diameter is greatly reduced, the disassembly is convenient, and the maintenance cost is low; the heating is fast, the power consumption is low, the heating device is arranged locally, the temperature rises quickly, the brand ceramic heating ring, 380V voltage design, high power density, long life ; Modular combination, clamping parts can be arbitrarily matched with injection parts to meet customer needs and reserve installation positions;Clamping part: high rigidity clamping mechanism, strong self-locking ability, to ensure minimal deformation of the template. The tie rod spacing is designed according to the standard mold base, and the versatility is good. Large mold transfer stroke, suitable for deep cavity products; The processing precision is strong, and the important parts such as the template machine glue are precisely processed by imported machine tools to ensure that the parallelism accuracy is far better than the industry standard; for mold changing, the template is equipped with a T-shaped slider, which has high mold changing efficiency; the template has a strong bearing capacity, and the moving template adopts Hydraulic support can effectively prevent the template from tilting forward. The auxiliary mold supporting mechanism can be selected, which is suitable for the production of large-scale mud well molds; the widened doors and windows are suitable for core-pulling molds, which are neat and beautiful, and the tempered glass is bright and clean.

ITEMS | Units | TH630/S1 | |

INECTION UNIT | Screw Diameter | mm | 90 |

| Screw L/D Ratio | L/D | 30 | |

| Piston diameter | mm | 190 | |

| Shot Size(Theoretical) | cm3 | 29490 | |

| Injection Weight | g | 21233 | |

| Injection Pressure | Mpa | 82 | |

CLAMPING UNIT | Clamping Force | KN | 6300 |

| Clamping Stroke | mm | 900 | |

| Space Between Tie Bar | mm | 880*880 | |

| Max. Mold Height | mm | 900 | |

| Min. Mold Height | mm | 400 | |

| Eject Stroke | mm | 260 | |

| Eject Force | KN | 184 | |

OTHERS | Max. Pump Pressure | MPa | 17.5 |

| Pump Motor Power | KW | 66.9/67.6 | |

| Heat power | KW | 66 | |

| Hopper Capacity | Kg | 200 | |

| Oil Tank Capacity | L | 1050 | |

| Machine Weight | T | 25 | |