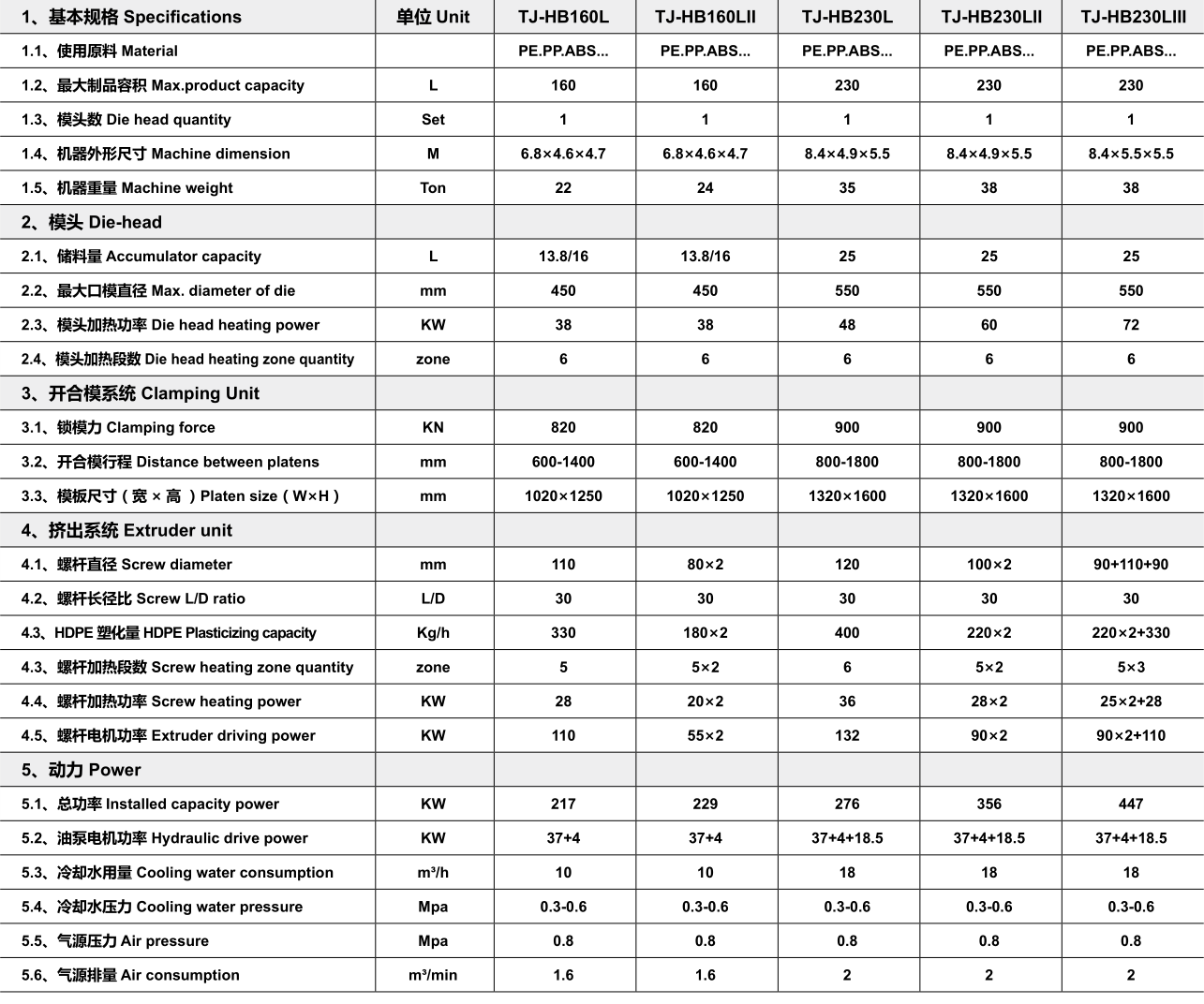

TJ-HB160 ~ 230L Chemical Packaging Blow Molding Machine

Tongjia tj-hb160l-230l Series hollow blow molding machine is a new generation of automatic blow molding machine specially developed for 120-220l closed barrel and open barrel. The equipment adopts hydraulic servo control and energy saving. The single ring barrel and double ring barrel produced are of good quality.

Add to quoteTongjia TJ-HB160L -230L series blow molding machine is a new generation of automatic blow molding machine specially developed for 120-220L closed and open top drums. The equipment adopts hydraulic servo control, can save more energy and produces single L ring drums and double L ring drums with good quality. Tongjia TJ-HB160L -230L series blow molding machine adopts storage die head, new runner design, fast color change, and can make multi-layer die head according to customer requirements. The equipment adopts a die shifting system to move back and forth to avoid the inconvenience caused by the movement of the overall extruder platform, and it is more convenient to change the mold.

Clamping system:Diagonal double tie bar center clamping bi-directional synchronous high precision linear guideway clamping device |

| Extrusion system: AC speed control + Hardened face gear reducer |

| Die head system: Special steel center-feeding die |

| Hydraulic system: All imported hydraulic valve + hydraulic servo control system |

Control system:Imported PLC + Europe imported complete machine control system (GEFRAN from Italy) / SIEMENS from Germany |

Note: the above data are for reference only. The company reserves the right to change the components and mechanical structure. The relevant contents involved in the purchase of equipment shall be subject to the contract.